Buyers And Sellers Of Packaging Machinery

Matthew

+44 (0)7866 791816

Steve

+44 (0)7966 421369

How To Set Automatic Labelling Machine

We also buy and sell used packaging machinery

Three Step Listing

Contact Us to Day

To Arrange A Vist

Price

(Relating To Age And Condition)

We Market For You

Setting Up Automatic Labelling Machine Applying Self-adhesive Labels.

1. Datum

The datum line to work from very depending on the type of labelling application but only really apply for Wraparound and Front and Back applications.

-

-Wraparound machines, the wraparound unit is the datum to set dispensing edge and guide rails to this point

-

-Front and Back datum is the center line of the conveyor/top hold belt. Set guide rails to the product. Start machine and stop the product at the dispensing edges to set head positions. Set one side at a time.

-

-Top labelling set guide rails to position product in the center of the conveyor the set head positions to the product

-

-Bottom labelling set guide rails to position product in the center of the conveyor the label over hang is the crucial setting.

2. Select the container to label together with the relevant labels rolls.

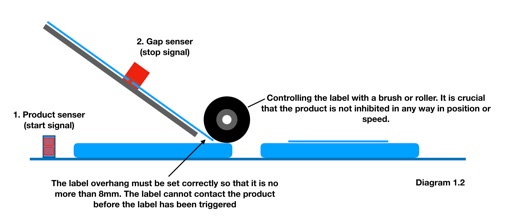

Place a container on the conveyor. Set the guide rails to the product on the conveyor. The guide rails must not contact the product wiles it is in motion a change in speed or position will in-pack label position/placement

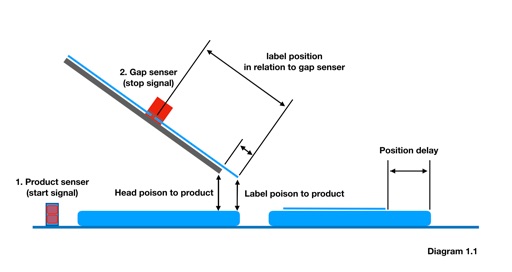

3. Set the label on the container at the correct position using vertical and linear adjustment on application head see diagram 1.1 and 1.2. Adjust the label head so that the dispensing edge is close to the product. The dispensing edge must not contact the web of the labels this can cause ripping and label application problems.

Once the labelling machine is adjusted start to set the label settings

4. Label over hang (the amount of label showing over the edge of the dispensing edge) See diagram 1.2

-

5.Label application delay (the time from the product senser to the label being applied)

-

6.Label application speed is crucial to label accuracy. The label speed should match the speed of the conveyor. Too fast and the label will crease the front edge. Too slow and the label will drag on the container or pull on the label web this has a direct impact on the accuracy and label position.

Maintenance

Daily

The machine should be kept clean, and free from labels and spilled products

Check web rollers and label dispensing beak are free from adhesive build up and clean

Check that product detection optics are clear and clean

Ensure all screw threads and slides are kept lightly lubricated and clean (do not use silicon lubricants)

Monthly

Check the product conveyor belt for signs of wear

Check drive belts for tension sign wear.

The video below demonstrate some of the leading and setting technique:

We Purchase Machinery And Can List You Packaging Machinery

Experience the pinnacle of performance with our top-tier machinery stock. From precision engineering to robust construction, we provide machines that stand the test of time. Ready to revolutionize your operations? The journey begins here

Matthew:

+44 (0)7866 791816

Steve:

+44 (0)7966 421369

Email:

Office:

+44 (0)1942 218476

scpackaging@hotmail.com

Office

107 Gathurst Road

Orrell

Wigan

Lancashire

WN5 8QJ

UK

Unit 15 Barrows Farm

Carr Mill Road

Billinge

Wigan

Lancashire

WN5 7TX

UK